A pioneering new project at Heriot-Watt University's National Robotarium is developing robots that can be launched from crewless vessels to inspect and maintain offshore wind turbines.

The future of clean energy relies heavily on offshore wind farms. However, their maintenance and inspection have long been a significant challenge. This may all change with the new groundbreaking project at Heriot-Watt University's National Robotarium which is poised to transform the industry. This research aims to develop robots which are capable of being deployed from crewless vessels, this initiative is set to make offshore wind farms safer, more efficient, and cost-effective.

Offshore wind farms play a pivotal role in the global transition to sustainable energy sources. They harness the power of wind over vast expanses of the ocean, generating clean electricity without the pollution which is generally associated with fossil fuels. Yet, despite their environmental benefits, these wind farms face numerous obstacles especially when it comes to maintenance and upkeep.

The most prominent issue with traditional methods of offshore wind farm inspection and maintenance is that it is both costly and logistically challenging. Sending human divers or helicopters to wind farm sites has been the most common method, but these approaches come with steep price tags and a significant number of operational complexities.

The Maintenance and inspection in these remote offshore environments are fundamentally risky and require an immense level of skill and training. Divers and helicopter pilots face perilous conditions, which can range from high winds to turbulent waters, and unpredictable weather patterns all of which being miles away from any aid. This presents a considerable danger to both personnel and equipment.

Additionally, Offshore wind farm inspections and maintenance can be time-consuming and complex. Weather delays and logistical challenges can result in prolonged downtime, and reduced energy production, which ultimately leads to higher costs.

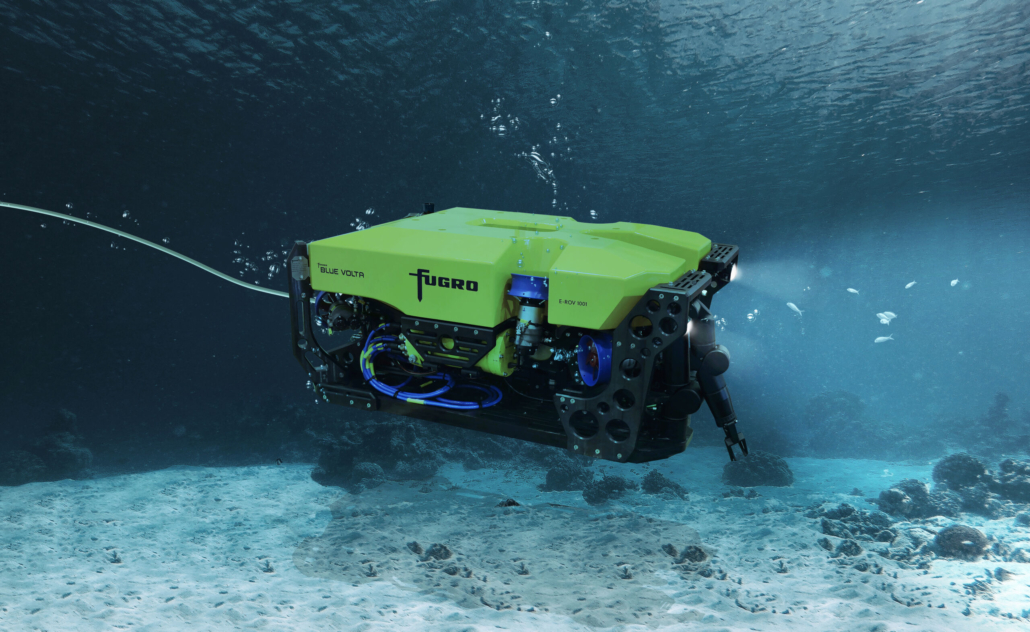

Heriot-Watt University's National Robotarium seeks to address these challenges by introducing underwater robots designed specifically for offshore wind farm maintenance. These robots can be launched from crewless vessels, offering several key advantages. Equipped with advanced sensors, cameras, and manipulation tools these robots are able to perform a wide range of maintenance and inspection tasks, from cleaning turbine blades to replacing components.

Eliminating the need for direct human input such as divers and helicopter crews, the use of underwater robots significantly reduces the inherent risks associated with offshore wind farm maintenance. Robots have the potential to operate in some of the world's most remote and hazardous conditions all whilst minimising, if not competing eradicating, the risk to human lives.

Remote robots also can improve costs as these robots can work around the clock and require minimal human intervention. This can lead to cost savings in terms of personnel, equipment, and operational downtime. Additionally, the initial investment in robot development can be offset by long-term cost reductions. These underwater robots can also improve costs as they can swiftly and accurately inspect wind turbines, identifying issues before they escalate. This proactive approach helps prevent costly breakdowns and ensures the continuous, efficient operation of offshore wind farms.

The development of underwater robots for offshore wind farm maintenance is poised to revolutionize the clean energy industry. By enhancing safety, reducing costs, improving efficiency, and ensuring the long-term sustainability of wind farms, these robots are instrumental in accelerating the transition to a cleaner, more sustainable energy future. As the project at Heriot-Watt University's National Robotarium progresses, it brings us one step closer to harnessing the full potential of offshore wind energy while safeguarding the environment and workers alike.