Volunteers' Week, which takes place from June 1-7, celebrates the millions of people in the UK who dedicate part of their lives to volunteering. The Society is proud to have many volunteer members from each of our professional sectors.

Like many people who volunteer as a STEM Ambassador, I wanted to give something back to society. I enrolled at the London branch despite not really knowing what I could do or how I could fit in, aware that it would be added responsibility on top of my full-time work and active involvement in several other voluntary organisations.

The process of becoming a STEM Ambassador is relatively straight forward, particularly if you are a member of the Society and registered with the Engineering Council. It can all be done online and includes a DBS check and training package. Once accepted, you then receive e-mails from your local STEM hub outlining opportunities for future involvement as an Ambassador. I was offered work in the following areas:

- Supporting an exhibition or event

- Interactive activity

- Presentations, talks + Q&A

- Hosting a visit

- Judging a competition

- Mentoring

So, there I was, registered and trained but still not having taken the plunge when, out of the blue, I was asked by a colleague who delivers ‘life skills outreach’ to youth groups if I could help a youth club that he had recently visited. They were in need of some engineering advice. Apparently, they had built an electric race kit car, but when raced it was not as competitive as the other cars in the same formula. Well, my mind was made up. It was at a location close to where I work, it was on an evening that I was free from other commitments and it was a task which I was familiar with. Or so I thought.

Background

The youth club in question is St Andrew’s in Westminster. It is the oldest youth club in the country, dating back to 1866, and supports the surprisingly large local youth community. The club runs many activities, ranging from cooking to fitness, and is supported by many organisations, including corporate supporters, livery companies and various trusts and foundations. One of the corporate supporters is The Society of Motor Manufacturers and Traders (SMMT). Its HQ is close to the club and it was the SMMT sponsorship that got the club involved in the Greenpower, Formula 24 (F24) electric race car project.

Task

Added to the club’s ownership of the first uncompetitive car, in 2019 it took delivery of another kit for a second car. So, my task was twofold. First, guide the build of the new car and, secondly, work out how to make the first car competitive. The problem was that I started the role in May and the next race was the beginning of September, with the summer holidays in between. However, everybody loves a challenge!

The first car is pictured above. The kit consists of a steel spaceframe with solid adjustable suspension, powered by a 24v sealed electric motor. The body work was designed and fabricated at the club using mainly wood and foam. It certainly looked the part, but unfortunately lagged behind the other cars in the same class. The winner of the race series is not determined by out and out speed, but how far the car can travel in laps, utilising one set of batteries. Clearly, it looks aerodynamic, but was let down in the power to weight ratio. My aim was to concentrate on building up the new kit and, with the help of the young people, to design and fabricate a lightweight and aerodynamic body, all within a few weeks.

Further details on the kit and the race series can be found at the following link: https://www.greenpower.co.uk/sites/default/files/uploads/F24%20Guide%202016%20v2.pdf

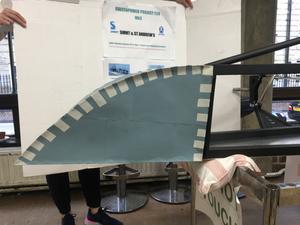

The club has no workshop facilities, but fortunately the kit can be built up with limited tooling and the build manual is comprehensive. Pictured right is a photo at the start of the body design/fabrication, utilising CAD (Cardboard Aided Design!). The nose cone is the face of the car, so between the young people and I we mocked up several models until they decided on this shape.

A quick note on the young people involved: their ages range from 8-16, girls and boys all with varying degrees of abilities and enthusiasm. I must add that, before we got to this stage we had to firstly address the logging of the kit spares and organisation of the hand tools − no mean task, as many of them were unfamiliar with the names of the tools and their uses.

The nosecone was completed (pictured left), using a 0.9mm aluminium sheet, sponsored by the IRTE North London Centre. The objective was to make the weekly sessions interesting with bite size chunks of hands-on action. In this stage, the young people finished off the cutting of the aluminium and then drilled and pop riveted the nosecone together. The main aim was to skin the spaceframe in an aerodynamic body conforming to the F24 Formula regulations. As a serving member of REME, I was able to use some inhouse facilities to prepare work for the weekly sessions, as working in the club on a table has limitations. A point to note is that F24 is fundamentally aimed at schools, where there is access to some sort of design and technology facilities. That said, with ingenuity and a little outside assistance these race cars can be built with the minimum of resources.

Race day was rapidly approaching and, similar to those build-up programmes on the television, we were very active right up to the day before the race. At this stage it still had not been driven more than a few feet inside the club. Everything appeared to work but final tuning would have to take place on the track. Although the F24 Race Series consists of 19 races throughout the year, in various parts of the country, the club had only ever competed in the September race, which is held at Dunsfold Park (the Top Gear track).

Outcome

Race day was a success; the club fielded six drivers aged between 11-16 (pictured below), and they all took part in the practice session and the two 90 min races. We had our fair share of technical problems, consisting of a few loose nuts and bolts and two ruined tyres, but overall the team did well and ended up middle placed. During gaps in the racing, I was able to visit the pits of the other teams and tap into their extensive race knowledge, and investigate how they squeezed out more laps than we did. This completed the first part of the task, and once back in London we put the new car on display and set about making the first car competitive. Unfortunately, this involved totally destroying the previous bodywork, which the young people enjoyed immensely as they were given a free hand to get it stripped down.

Future

I am glad to say that there is a future. St Andrew’s is happy for its STEM Ambassador to serve on. The first car is now back to its chassis and the plan for 2020 was to build it up slowly to mirror the new car, but incorporating several modifications gleened from the other teams. The objective was to compete in two of this year’s latter races, utilising both cars, but the impact of Covid-19 has temporarily put that on hold.

As an Ambassador you are obliged to log the amount of hours you have committed with your local STEM hub. This donated time is acknowledged by an annual award that can be used to demonstrate your commitment to STEM and also to bolster your CPD record.

Reflection

The route I have taken as a STEM Ambassador is different to most because I have remained with one organisation. But the fundamental objectives of the scheme have hopefully been met, as I have been able to impart some knowledge and skills to a group of youngsters who may never have had the opportunity to experience engineering previously. Overall, it is a worthwhile and rewarding position to hold and I recommend it to any engineer, no matter how small the amount of time you can donate. Further details on becoming a STEM Ambassador can be found at the following link:

https://www.stem.org.uk/stem-ambassadors/join-stem-ambassador-programme

Roy Duffin MBE IEng FSOE FIRTE