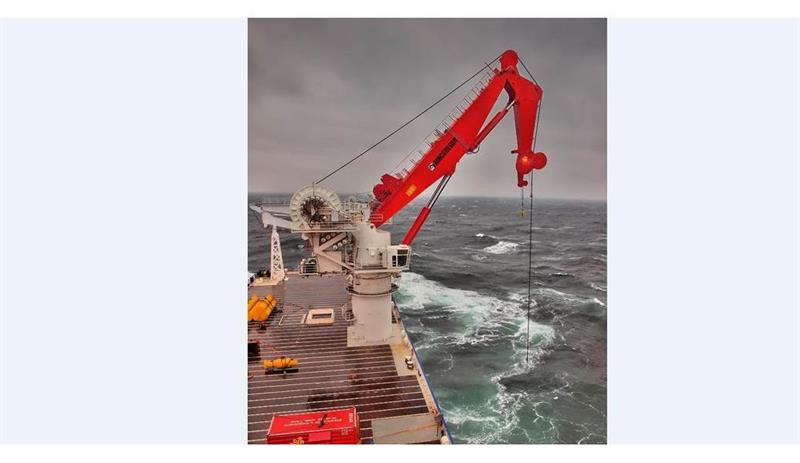

Heave compensation systems are used to reduce the influence of waves upon offshore operations. We explore how these systems work and the benefits that they bring

Heave compensation is a type of vertical motion compensation used to reduce the effect of waves on offshore operations, such as lifting and drilling. Both passive and active systems may be used.

Passive heave compensation (PHC) systems use springs and sometimes also dampers, and they work in essentially the same way as the suspension in a land vehicle. Active heave compensation (AHC) systems, meanwhile, use a control system with powered actuators that actively compensate for movements detected by sensors. Some motion compensators are intended to reduce the peak accelerations and stresses due to motions in any direction.

Heave compensation is focused on the vertical motion of a vessel, caused by the action of waves. It attempts to reduce the total range of this motion. “The purpose of heave compensation is to protect the ship, the lifting equipment, the payload, the landing area and the lift area from unintended damage,” says Peter Berting, director of global business development at operating company Huisman Equipment.

PASSIVE HEAVE COMPENSATION

PHC systems place a spring between the moving hull of the vessel and operation to be compensated, such as a crane hook or drill head. These systems provide a reliable way of reducing forces, where the load is well anchored or is very heavy, providing great inertial stability. It is less effective at eliminating relative motions for very precise alignment.

A PHC may be more generally described as a mass spring system, which stabilises the mass in a nominal position for which the spring is unloaded. When properly configured, this reduces the transmission of movements caused by the action of waves. However, if the supporting vessel settles in a different position, an imbalance between the weight of the mass and the spring will cause unwanted movement. More significantly, if the frequency of the wave excitation matches the natural frequency of the mass spring system, a resonance may occur. If this happens, the wave motion may be amplified rather than compensated.

Typically, spring force increases with extension or compression. The very large springs required to compensate masses of tens or hundreds of tons are typically gas springs. A balanced heave compensation (BHC) system uses a mechanical mechanism to give a more constant force, similar to the way that a balanced-arm lamp works.

“PHC systems do not require external power and controls. This makes them very reliable in operation. They create a more or less constant load in the lifting equipment. This implies that the load position cannot be accurately controlled and is determined by the supports of the load. They can be configured as a shock absorber, overload protection, or slack wire prevention system. Also they can be configured as a damper, such that energy is dissipated, which may avoid resonance and reduces the motion," Peter Berting, director of global business development at operating company Huisman Equipment.

ACTIVE HEAVE COMPENSATION

AHC systems are typically used for cranes in lifting and construction applications. They use a sensor to detect movement of the vessel and control an actuator to compensate for this movement at the end effector. Sensors are usually either some form of inertial measurement, a high-accuracy satellite navigation system, or a hybrid system combining both technologies. Actuation may involve hydraulic cylinders, sometimes integrated into a lifting hook, or may be applied directly to winching equipment.

“Active systems can drive a load to virtually any amplitude but will require large amounts of energy to do so. The active-passive system combines elements of both methods. Such systems have a passive part that balances the heavy load against a massive spring in the form of a bank of nitrogen. The active part is then only used to make the adjustments necessary for lifting or pulling, for example. These energy requirements are much lower since the passive side is holding the dead weight of the load,” Lene Stray, new business and marketing manager at load handling solutions and services provider MacGregor Norway.

There are two types of AHC used in winch gear – linear and rotary. Linear AHC uses a hydraulic cylinder, acting as a linear actuator, to adjust the cable length. This separates the lifting function of the winch drum from the heave compensation function. Linear AHC systems may be top mounted on the vessel or inline (hook-mounted) between the travelling block and the lifting hook. Rotary AHC, or cranes with heave compensation, directly control the winch drum so that it performs a dual function to control both lifting and provide AHC. Rotary systems may use electric or hydraulic motors to drive the winch.

“A typical system is generally designed to perform more than just heave compensation while lifting in water,” adds Stray. “Sub-modes such as Active Rope Tension (ART) are also used when force-control, rather than position control, is necessary, for instance when lifting an object out of a muddy bottom.”

A major challenge of AHC is controlling the motion sufficiently fast. The drive system has to respond swiftly on the measured motion to be able to compensate for the irregular wave motion. The compression flexibility of oil and the inertia of electro motors often slow down the response speed of the AHC system. Secondary hydraulic control systems allow such fast control in hydraulic drives. Electrical drives require a lot of extra torque to accelerate the inertia of the E-motors sufficiently fast. Both systems normally utilise energy storage systems to respond sufficiently quickly.

“To design a well- functioning heave compensation system, it is important to study all requirements: stroke, velocity, accelerations, load and time sequences,” concludes Berting.

HEAVE COMPENSATION APPLICATIONS

Heave compensation is important for many offshore operations, including oil and gas, as well as wind turbine installation and maintenance. It is used wherever a floating vessel is required to accurately align and maintain the position of equipment relative to the sea bed. It may also be useful in the transfer of equipment between vessels. Correction for relative movements in these applications improves safety, achieves greater accuracy, reduces damage to equipment and extends the range of weather conditions over which operations can be carried out. Special purpose heave compensation systems are used for different applications.

“Typically, a customer will specify that their equipment should be fully operational for a given expected wave height. However this is difficult to predict since wave height does not correlate to heave motions predictably and it is the vessel's heave motions that must be compensated for. Factors such as the vessel's hull design and loading, the vessel's heading, wave swell direction and period, and more come into play,” Scott Garriot, project engineer & multimedia developer at MacGregor Norway

Garriot continues: “In the end, predictions must be made for how the vessel can be expected to move, given a particular set of values for ship heading, wave height and period. With simulation of these seas and a digital vessel, we are able to run our system in real-time to show it will work and to ascertain power requirements long before anything is designed.”

Drill string compensators, also known as wireline tensioners, are a special type of heave compensation used to reduce the force on a drill bit, or drilling riser. They are effectively very large springs, which allow the drilling riser to extend and compress as the vessel moves up and down. This prevents the drill bit from pulling out of the hole and reduces tensile and compressive forces on it. Drill string compensators typically use pneumatic cylinders as the spring medium. They may be top mounted on the vessel or hook-mounted between the travelling block and the lifting hook. They typically consist of a number of large pneumatic springs arranged in a concentric ring around the drilling rig.

When lifting very heavy objects, inertia may prevent the vessel from riding over waves. This could cause waves to surge over the deck, with the risk of personnel being swept overboard or even the vessel being lost. Very high forces may also be encountered, potentially damaging lifting gear. Inline PHC acts very much like a land vehicle’s suspension system, providing a degree of compliance between the vessel and the object being lifted. These systems also often consist of a number of large pneumatic springs arranged in a concentric ring, in this case around the winch cable.

Beyond the traditional oil and gas applications, heave compensation is used wherever accurate alignment is required between lifting gear on a floating vessel and equipment anchored to the sea bed.

Offshore wind turbine installation may seem an obvious application, but these operations usually avoid the need for heave compensation in one way or another. Traditional offshore wind turbine installations, which are in shallow water, reduce the need for heave compensation by using installation vessels that are equipped with extending legs. These enable them to stand on the sea bed during installation. Monopiles aresingle structural elements that supportthe entire vessel’s load. Transition pieces can then be lowered without any relative movement between the sea bed and the lifting gear. Final assembly of the tower, nacelle (housing), rotor hub and rotor blades also makes use of this stable platform.

However, heave compensation may still be useful even when the lifting equipment operates from a bottom-founded structure. Wave motion hitting the payload may cause unacceptably large load variations in the lifting slings and shackles if the payload has a large added mass and/or drag. For such a situation, heave compensators are useful. The emerging technology of floating wind turbines allow for full assembly of the wind turbine on to the floater at the quayside. The complete floating turbine can then be towed into position and anchored.

For other applications, such as wind turbine supply and the installation of floating wind turbines, heave compensation is desirable. This type of accurate construction application may require more sophisticated motion compensation that stabilises more degrees of freedom than the vertical translation dealt with by a heave compensator.

By Jody Muelaner